Choosing the right warehouse storage system isn’t just about holding inventory—it’s about space efficiency, flexibility, safety, and cost control. Two of the most common solutions are stack racks and pallet racking systems, and while both have their place, they serve very different operational needs.

If you’re weighing stack racks vs. pallet racking, this guide breaks down the real-world differences, use cases, and decision factors so you can choose the system that actually fits your operation—not just your floor plan.

What Are Stack Racks?

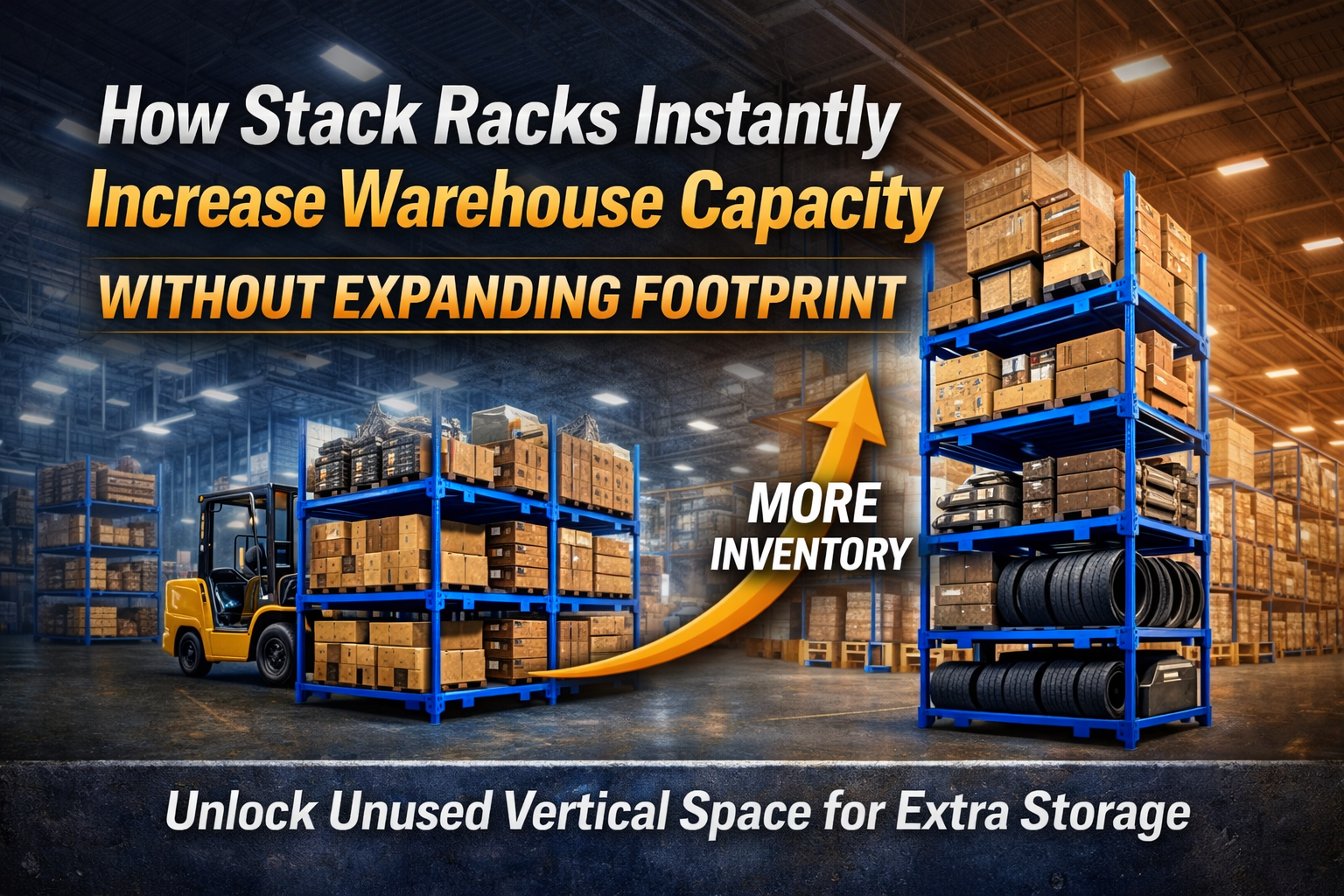

Stack racks are freestanding, portable steel racks designed to store materials vertically without being anchored to the floor. They can typically be stacked 4–5 units high, moved with a forklift, and reconfigured as your needs change.

Key characteristics:

- No permanent installation

- Portable and stackable

- Ideal for odd-sized or non-palletized loads

- Can be nested or dismantled when not in use

Stack racks shine in environments where flexibility matters more than fixed infrastructure.

What Is Pallet Racking?

Pallet racking systems are permanent or semi-permanent storage structures anchored to the floor and often to the building itself. They’re engineered for high-throughput operations using standardized pallets and predictable inventory flows.

Key characteristics:

- Fixed layout

- Designed for palletized goods

- High selectivity and SKU density

- Requires professional installation and permits in many jurisdictions

Pallet racking excels in stable, high-volume operations with consistent storage requirements.

Stack Racks vs. Pallet Racking: Side-by-Side Comparison

| Feature | Stack Racks | Pallet Racking |

|---|---|---|

| Installation | None | Professional installation |

| Mobility | Fully portable | Fixed |

| Flexibility | Very high | Low |

| Best for | Variable loads, overflow, short-term storage | High-volume palletized inventory |

| Upfront cost | Lower | Higher |

| Scalability | Modular, add as needed | Expansion often disruptive |

| Floor anchoring | Not required | Required |

| Seasonal use | Excellent | Poor |

When Stack Racks Are the Better Choice

Stack racks are ideal if your operation includes:

✔ Seasonal or Fluctuating Inventory

Peak seasons, promotional surges, or contract-based inventory demand a system that can scale up and down quickly.

✔ Odd-Sized or Non-Palletized Loads

Tires, metal parts, construction materials, automotive components—items that don’t sit cleanly on pallets are a perfect fit.

✔ Temporary or Pop-Up Warehousing

3PLs, overflow warehouses, job sites, and short-term leases benefit from storage that moves with you.

✔ Operations That May Relocate or Reconfigure

If your layout changes often, fixed racking becomes a liability. Stack racks adapt without demolition or downtime.

When Pallet Racking Makes More Sense

Pallet racking is often the right solution if you have:

✔ High SKU Count with Consistent Flow

Distribution centers handling thousands of SKUs daily benefit from fixed pick faces and narrow aisle layouts.

✔ Long-Term Facility Stability

If you own the building and don’t expect major layout changes, pallet racking can be optimized for maximum density.

✔ Automated or Semi-Automated Handling

AS/RS systems, conveyors, and robotics integrate far better with permanent racking systems.

Cost Considerations: More Than Just the Rack Price

Many buyers focus only on upfront cost—but total cost of ownership tells the real story.

Stack racks reduce costs by:

- Eliminating installation expenses

- Avoiding permit and engineering fees

- Reducing reconfiguration downtime

- Lowering damage from floor stacking

Pallet racking adds hidden costs:

- Installation and anchoring

- Reconfiguration labor

- Downtime during layout changes

- Long-term inflexibility

For operations with uncertainty or growth ahead, stack racks often deliver higher ROI.

Safety and Compliance: A Critical Factor

Both systems can be safe when properly used—but risks differ.

- Stack racks reduce unstable floor stacking and improve load containment.

- Pallet racking requires regular inspections, load signage, and strict compliance with rack ratings.

In dynamic environments, stack racks often reduce risk simply because they’re less rigid and easier to adjust correctly.

The Hybrid Approach: Best of Both Worlds

Many modern warehouses use both systems together:

- Pallet racking for core SKUs and long-term inventory

- Stack racks for overflow, specialty items, or seasonal volume

This hybrid strategy delivers maximum flexibility without sacrificing efficiency.

Final Verdict: Which Storage System Fits Your Operation?

Choose stack racks if you value:

- Flexibility

- Portability

- Lower upfront investment

- Adaptability to change

Choose pallet racking if you need:

- High-density pallet storage

- Permanent layouts

- Automation compatibility

If your operation is evolving—or you simply want storage that works with your business instead of locking it in—stack racks are often the smarter first move.

Ready to Optimize Your Warehouse Storage?

Whether you’re looking to buy or rent stack racks, or want help designing a hybrid storage solution, the right system can unlock space, improve safety, and cut costs—fast.

👉 Request a quote or layout consultation today and turn unused vertical space into productive capacity.