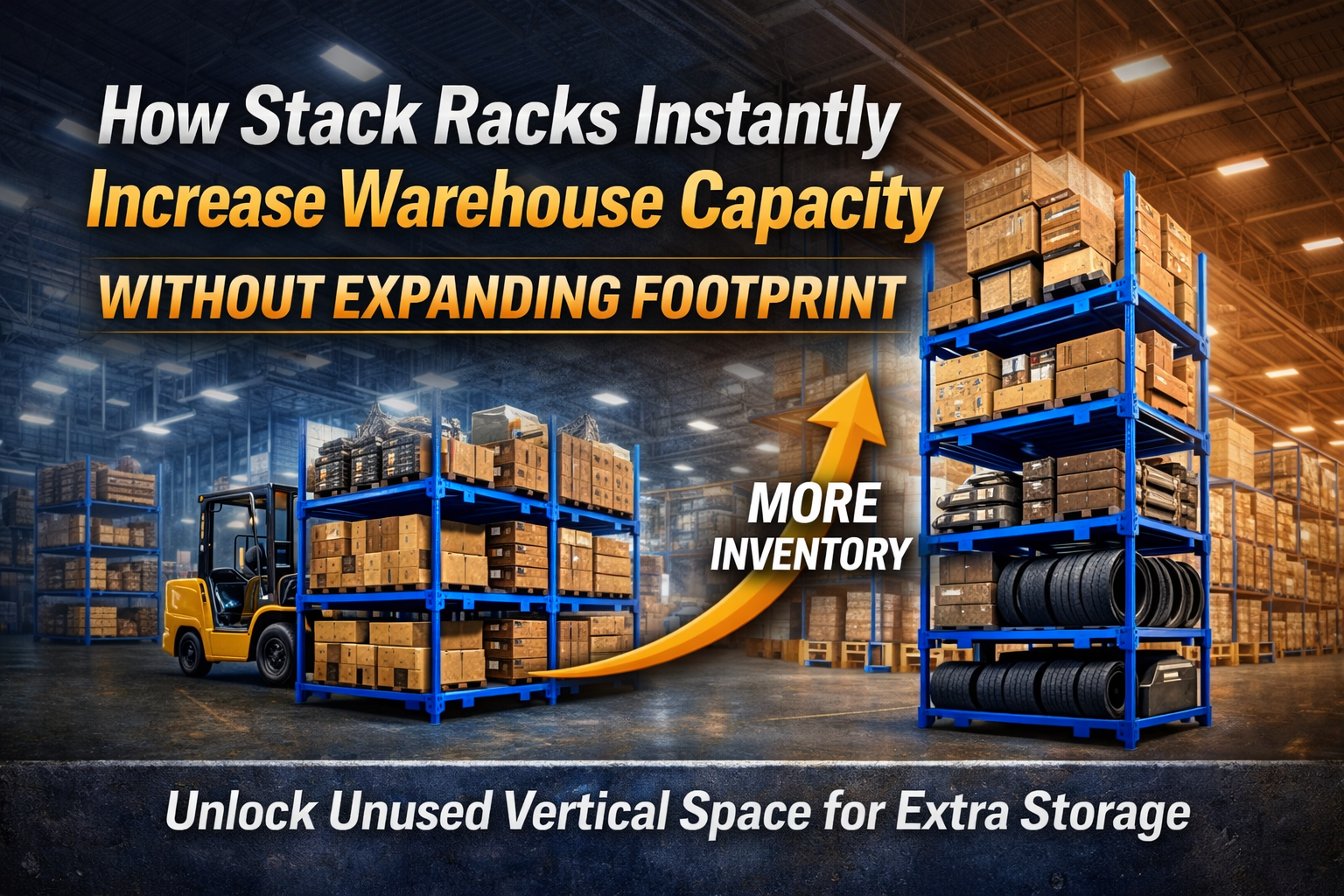

Warehouse space is expensive—and expanding it is often slow, disruptive, and capital-intensive. The good news? Many operations are sitting on unused vertical space. Stack racks unlock that space immediately, allowing you to increase storage capacity without adding square footage or committing to permanent infrastructure.

Here’s how stack racks work, why they’re effective, and when they make the most sense for your operation.

The Hidden Capacity Problem in Most Warehouses

Walk through almost any warehouse and you’ll notice the same issue:

inventory spread across the floor, stacked no more than one or two levels high, with empty air above it.

This happens because:

- Floor stacking creates safety risks at height

- Pallet loads vary in size and stability

- Fixed racking isn’t flexible enough for all SKUs

The result? You’re paying for cubic footage—but only using a fraction of it.

What Are Stack Racks (and Why They’re Different)?

Stack racks are freestanding, forklift-handled steel racks designed to stack safely and efficiently—often 4 to 5 units high—without being bolted to the floor.

Unlike pallet racking, stack racks:

- Require no installation

- Can be moved, reconfigured, or removed in minutes

- Support odd-sized or non-palletized loads

- Stack vertically with engineered load ratings

They turn vertical air into usable storage—fast.

5 Ways Stack Racks Increase Warehouse Capacity Instantly

1. They Convert Vertical Air Into Active Storage

Stack racks allow you to build upward safely, turning wasted overhead space into structured storage. In many warehouses, this alone can increase usable capacity by 30–60%.

No construction. No downtime. Just vertical efficiency.

2. They Eliminate Inefficient Floor Stacking

Floor stacking forces wide aisles, irregular pile heights, and conservative limits for safety. Stack racks standardize load height and footprint, enabling tighter, more efficient layouts.

More inventory in the same space—without compromising safety.

3. They Adapt to Variable Load Sizes

Not everything fits neatly on a pallet. Tires, metal parts, long materials, bulk cartons—stack racks handle these loads without forcing awkward pallet solutions that waste space.

Better fit = better density.

4. They Create Flexible Overflow Zones

Seasonal peaks and inbound surges often overwhelm fixed racking. Stack racks can be added exactly where needed, then nested or removed when volume drops.

That means:

- No permanent expansion

- No unused infrastructure in slow periods

5. They Improve Layout Flow and Pick Paths

Because stack racks are modular, they can be positioned to support:

- Shorter pick paths

- Cleaner product zoning

- Clear forklift travel lanes

Efficiency improves while capacity increases—a rare double win.

Stack Racks vs. Adding Pallet Racking or Expanding the Building

| Option | Cost | Speed | Flexibility | Disruption |

|---|---|---|---|---|

| Stack Racks | Low | Immediate | High | Minimal |

| New Pallet Racking | Medium–High | Weeks | Low | Moderate |

| Building Expansion | Very High | Months | None | Major |

Stack racks are often the fastest and lowest-risk way to gain capacity—especially when future needs are uncertain.

Best Use Cases for Stack Racks

Stack racks are especially effective in:

- Manufacturing facilities

- 3PL and contract warehousing

- Automotive and industrial parts storage

- Seasonal or promotional inventory

- Temporary or pop-up warehouses

If your inventory mix changes—or your space needs fluctuate—stack racks keep you agile.

Safety and Compliance Benefits

Properly rated stack racks:

- Reduce unstable floor stacking

- Improve load containment

- Simplify compliance with height and weight limits

When used correctly, they’re often safer than improvised stacking or overextended pallet racking.

The Bottom Line: More Capacity, Zero Expansion

If you’re out of space but not ready to build, move, or install permanent racking, stack racks offer an immediate solution.

They let you:

- Store more inventory

- Use vertical space efficiently

- Stay flexible as your operation evolves

All without expanding your warehouse footprint.

Ready to Unlock Hidden Capacity?

Whether you need to rent stack racks for peak season or purchase a scalable solution, the right configuration can transform your space in days—not months.

👉 Request a stack rack layout or quote today and start using the space you already pay for.